Painting

Expert tips for painting your Woodhouse Timber products

Products in our Edgeline® and Weatherproof® ranges come pre-primed with genuine architectural primers and are ready for the final top coating following installation on the job site. Read on for all you need to know about topcoat selection and application for each product type.

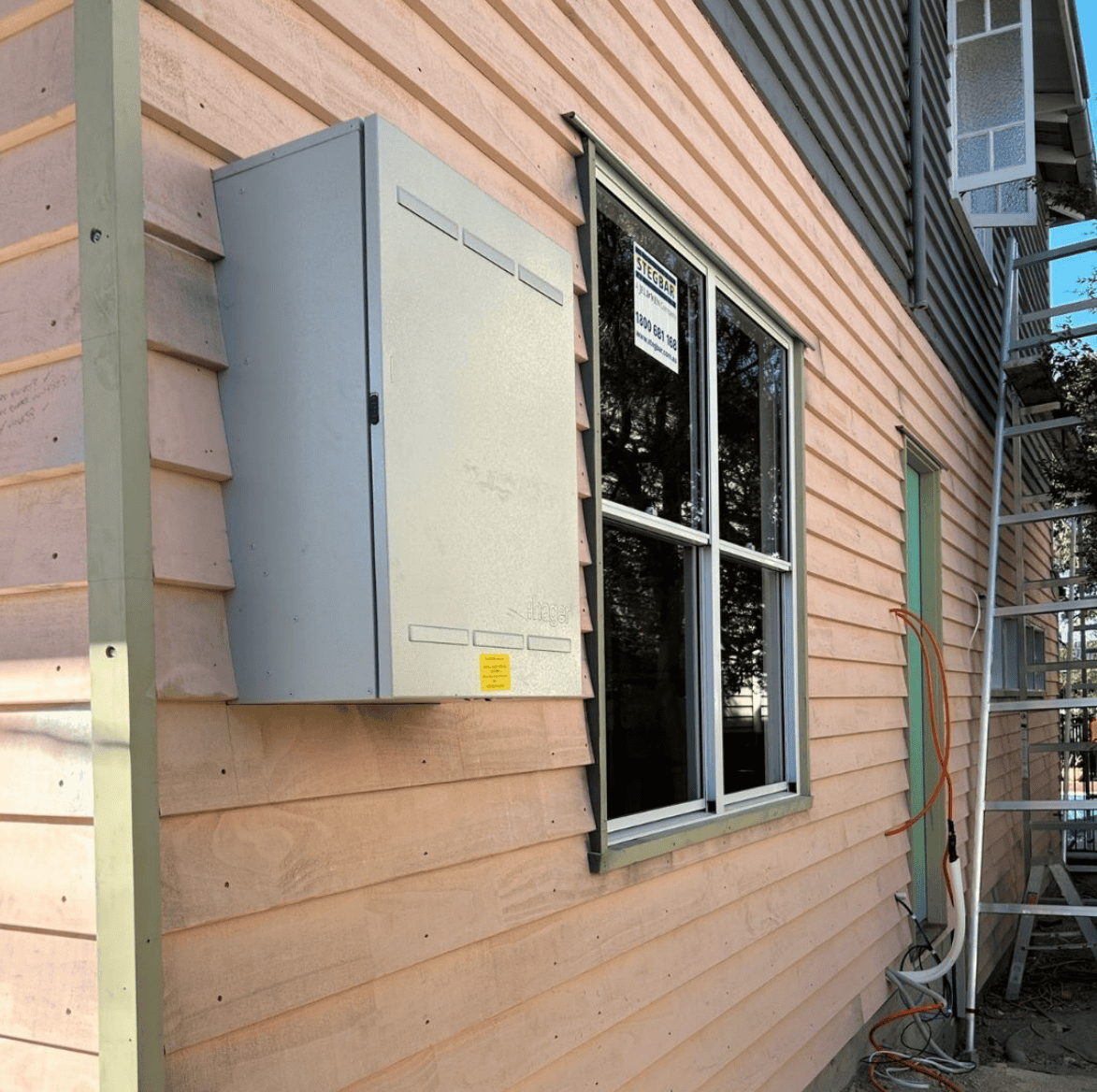

Woodhouse Weatherproof Paint Selection

- Woodhouse Weatherproof® products are factory coated with an architectural oil-based alkyd primer manufactured for Woodhouse by Dulux®.

- Woodhouse recommends selecting Dulux® Weathershield® exterior paints for optimum compatibility with and protection of Woodhouse Weatherproof® timber products.

- Where this cannot be achieved, choose durable and UV-resistant exterior paint from a reputable manufacturer. The oil-based alkyd primer formulation applied to Weatherproof® products can be overcoated with most premium water—and oil-based exterior paints.

- Water-based paints are highly flexible and offer improved UV resistance over oil-based paints, which means they are often better equipped to deal with the expansion and contraction of the timber substrate and the rigours of demanding outdoor environments.

- Oil-based paints may be harder-wearing in certain applications—for example, on exterior window and door trims—but they tend to become harder and more brittle with age. Their poor durability in locations exposed to high levels of ultraviolet light can also cause these paints to become chalky and/or fade over significantly shorter timeframes than water-based paints.

- Water-based exterior paints generally offer better performance than oil-based exterior paints upon application to Woodhouse Weatherproof® products.

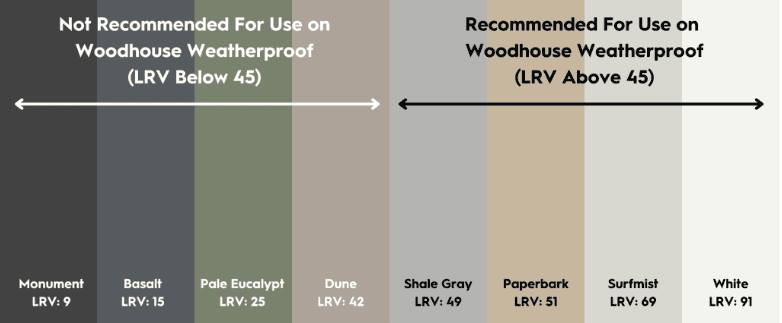

- When choosing colours, consider the impact of the topcoat colour on the performance of the timber substrate. Dark colours with a light reflective value (LRV) of 44 and below absorb light and can raise ambient temperatures on the surface of building materials. For softwood products like Weatherproof®, this can lead to surface checking, distortion, and resin bleed. We recommend paint colours with an LRV of 45 and above.

Painting Steps

- Woodhouse Weatherproof products achieve best performance when topcoats are applied within eight weeks of installation. If more time has elapsed and the primer appears chalky or loose, lightly sand these areas and re-coat with wood primer.

- Seal cut ends, notches and penetrations with an in-can timber preservative such as Tanalised Enseal, followed by a quality wood primer such as Dulux Timber End Sealer, available in Woodhouse Pink.

- Fill nail holes with wood filler, then lightly sand these areas to an even finish.

- Ensure the timber surface is free of dirt and contaminants.

- Finish dry timber with two or more applications of a premium exterior topcoat, following the manufacturer’s specifications. We recommend Dulux® Weathershield®!

- Note that some cladding and lining products may benefit from applying an initial topcoat before installation.

Over 40 years of trusted quality

Topcoat Colour Selection for Exterior Products

When choosing topcoats, select lighter colours with a light reflective value (LRV) of 45 to 100 (pure white = 100). Dark colours with an LRV of 44 or less will generate high surface temperatures, increasing the risk of surface checking, shrinkage, distortion, and resin bleed.

Woodhouse Edgeline Paint Selection

- Woodhouse Edgeline products are factory-coated with a multi-coat, water-based priming system compatible with most premium interior paints.

- For the best results, select a high-quality, hard-wearing enamel door and trim paint. These paints are usually thicker and have a higher viscosity than wall and ceiling paints, resisting ‘sag’ in vertical applications while drying to a smooth and consistent finish.

- Specialised enamel door and trim paints have also been designed to withstand the bumps, scrapes, and scratches typical of a modern home. Timber mouldings are often prone to impact from furniture, brooms, mops, vacuum cleaners, pets, and children and will benefit from the protection provided by hard-wearing paint.

- Water-based enamels typically emit less odour than oil-based enamels and are much more resistant to yellowing in low-light areas.

- Oil-based enamels usually achieve a higher sheen level than water-based enamels and level off to a superior surface finish following application (meaning fewer brush marks).

- Glossy paints with a high sheen level are generally more durable and easier to clean than matt and low-sheen paints, but they will also highlight areas of wear and tear on the surface of the timber moulding. Low—and semi-gloss paints are often recommended for door and trim applications as they strike a nice balance between the concealing benefits of flatter paints and the practical qualities of glossier paints.

Painting Steps

- Fill any nail holes with wood filler, then lightly sand these areas to an even finish.

- Spot prime where appropriate.

- Ensure that the moulding surface is free of dirt and contaminants. If necessary, clean gently with detergent and water to prepare for final finishing.

- Finish dry timber with two or more applications of a premium interior topcoat, following the manufacturer’s specifications.

Time-proven timber products, available around the country fast, flexibly & frequently.

When you need fit-for-purpose timber products manufactured to go the distance, you need Woodhouse.